In an increasingly electrified world, batteries have become vital components for powering numerous electronic devices, electric vehicles, and renewable energy storage systems. The quest for efficient and sustainable energy storage solutions has led to an ongoing debate about the merits of different battery technologies. One of these ongoing comparisons is between Ternary Lithium (NCM) and Lithium Iron Phosphate (LiFePO4) batteries. In this blog post, we will explore the key differences between these battery types and determine which one emerges as the superior choice.

1. Chemistry and Composition:

- Ternary Lithium (NCM) Batteries: NCM batteries are a type of lithium-ion battery that utilizes a cathode composed of a mixture of nickel, cobalt, and manganese oxides. This combination offers high energy density and good overall performance, making them suitable for various applications.

- Lithium Iron Phosphate (LiFePO4) Batteries: LiFePO4 batteries are a variant of lithium-ion batteries featuring a cathode made of lithium iron phosphate. These batteries are known for their exceptional thermal stability, safety, and long lifespan.

2. Energy Density:

Ternary Lithium (NCM) batteries generally have a higher energy density compared to LiFePO4 batteries. The nickel, cobalt, and manganese oxides used in NCM batteries enable them to store a larger amount of energy in a smaller and lighter package. This advantage makes NCM batteries particularly suitable for applications where weight and space constraints are important.

3. Safety and Lifespan:

LiFePO4 batteries are known for their excellent safety profile. They have a lower risk of thermal runaway, which reduces the likelihood of fire or explosion. Additionally, LiFePO4 batteries do not contain cobalt, which is associated with safety concerns in some other lithium-ion battery chemistries. These attributes make LiFePO4 batteries a reliable choice, especially in applications where safety is paramount.

LiFePO4 batteries also exhibit a longer lifespan compared to NCM batteries. LiFePO4 batteries are capable of delivering a significantly higher number of charge-discharge cycles, typically ranging from 2000 to 3000 cycles. This longevity makes them an ideal choice for applications requiring frequent cycling, such as energy storage systems.

4. High-Temperature Performance:

Ternary Lithium (NCM) batteries generally perform better at high temperatures compared to LiFePO4 batteries. NCM batteries have a higher operating temperature range, allowing them to maintain their performance in environments with elevated temperatures. This makes them suitable for applications where the battery may be exposed to extreme heat, such as electric vehicles operating in hot climates.

5. Cost Considerations:

One key aspect that influences battery choices is cost. Ternary Lithium (NCM) batteries typically have a lower production cost compared to LiFePO4 batteries. The materials used in NCM batteries are more abundant and easier to source. However, it's important to note that the cost of lithium-ion batteries is continuously declining due to advancements in manufacturing processes and economies of scale.

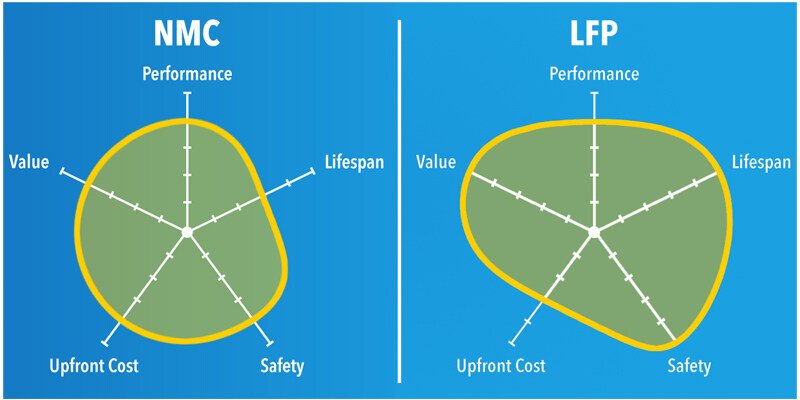

When comparing Ternary Lithium (NCM) and Lithium Iron Phosphate (LiFePO4) batteries, it's clear that each technology has its unique advantages and considerations. Ternary Lithium (NCM) batteries offer higher energy density and better performance at high temperatures, making them suitable for applications where power and space constraints are important. On the other hand, LiFePO4 batteries excel in terms of safety, long lifespan, and overall reliability. These batteries are well-suited for applications that prioritize safety, durability, and frequent cycling needs. Ultimately, the choice between these battery technologies will depend on the specific requirements and priorities of the intended application, keeping in mind factors such as energy density, safety, lifespan, high-temperature performance, and cost.

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent